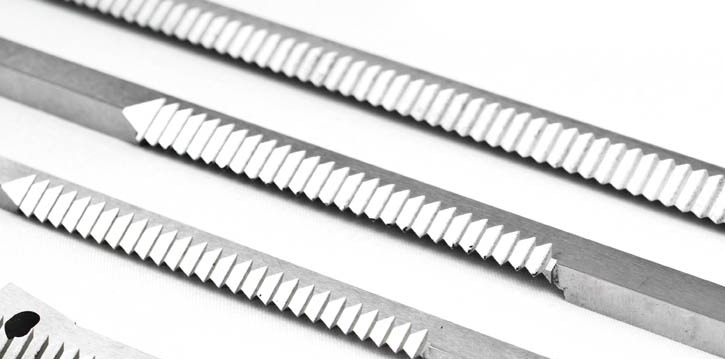

Packaging Knife Manufacturing

At Precision Edge, we know that a well-designed and efficient packaging operation can make the difference between a production line being regarded as a complete success, or a problem to be solved. As suppliers, designers and manufacturers of standard and bespoke machine knives to all industries, we’d like to help you find a solution to any automated packaging process problems you may be experiencing. Just some of the types of packaging equipment we frequently work on are considered below.

Bagging machines are typically used for powdered or granular products, with each bag filled with a pre-set weight or volume of material and then sealed. This works especially well for bulk food products. Less obvious applications of this process include the compilation of kits, for example bagging a predetermined list of nuts, bolts, washers, and so forth in a bag to be shipped with an item of self assembled furniture. While most fill and bag machines will be set up for continuous operation, semi-automatic machines can allow operators to trigger sealing manually when the bag is filled. When using tubing film or bagging material on a role for adjustable bag length, packaging knives can cut bags to the desired size in each instance. These bagging machines can therefore even be suitable for the packaging of bespoke products on a discreet basis.

The vast majority of thermoforming machines are used for food packaging. The plastic trays which are so important to provide sturdy and hygienic support for soft and brittle food products which would otherwise be crushed in transit are produced by small thermoforming operations. During thermoforming, plastic sheets are held in a clamp, and the centre of the sheet is heated and stretched over a mould before being allowed to cool. Food packaging knives are then used to trim off the excess material which held the sheet in the clamp. Industrial vacuum packing machines similarly use food packaging knives to remove unwanted material from around the product once packaging is complete.

Flow wrapping machines are geared more toward mass production. These higher speed machines can be very demanding on packaging blades as each item must be trimmed and sealed quickly and neatly so as not to impede the progress of the whole operation. Overwrapping machines are a similarly intensive environment where accurate cutting by well maintained packaging knives is key to the smooth running of the process. For high volume packing operations, packaging blades can be a weak link if they are not up to the task. Not only must such machine knives be correctly profiled and positioned, they must also yield good durability characteristics in a given application, which involves providing a consistent standard of performance throughout their lifespan. In pursuit of this goal, various aspects of packaging knife manufacturing including materials and coatings technologies come into play.

At Precision Edge, we believe our team can boast unparalleled expertise when it comes to finding solutions to tricky packaging process problems. Contact us to consult on any mechanised packaging operation, and especially in relation to packaging knife manufacturing.

Premium Refurbishment and Regrinding Service

We service Machine Knives for industries in the UK and Europe

Find Out More

PowerEdge technology - leading the performance knife range

We provide PowerEdge technology to industries throughout Europe

Find Out More