All About Our Rotary Moulder Scraping Blades

Comments Off on All About Our Rotary Moulder Scraping BladesHere at Precision Edge, we have an extensive collection of blades when it comes to the machine knives market. In operation since 1987, we are proud to provide our clients with a bespoke service and aim to supply the best quality knives, earning us a great reputation for meeting the needs of our different customer across various industries. Today we will tell you all about our rotary scraper knives.

The Benefit of Rotary Moulder Scraping Blades

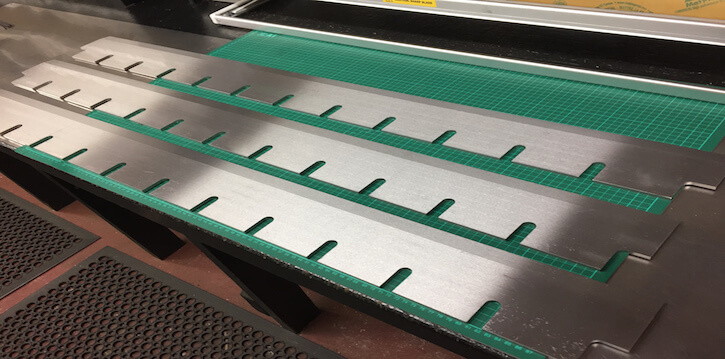

The benefit of using a rotary moulding machine rather than an embossing type of cutter is that it eliminates any cutter scrap. During the cutting process, any waste removed by a rotary scraper blade is eradicated from the process, so it will completely avoid catching inside the machinery further down the line. We manufacture rotary scraper blades to strict specifications, maintaining the critical dimensions of the product and keeping a clean and perfectly parallel edge will ensure they work as part of process reliably and consistently each time a new blade is fitted.

The Uses of Rotary Moulder Scraping Blades

Using an adjustable rotary scraper tool makes it possible to reconfigure the machinery, so you can turn out products of different sizes and specifications. As the blades are adjustable, this means that they enable you to fine-tune the tolerances, which thus advances the quality of each individual product, as well as reducing wastage. This has an advantage over attaching a fixed scraper knife to trim material, especially when you need to manufacture a product in repeated runs.

Mass Production

Not only can rotatory moulder scraper blades trim excess material without damaging the product itself, even with products that have more complex shapes. A moulding scraper separates the excess material which inexorably overflows the moulds. These high-performance rotary scraper blades are able to turn produce many thousands of products each hour, separating each individual item without damaging them, keeping waste away from the actual production process. It is important to maintain the thickness and edge continuity of the blades so to ensure consistent product thickness and ensure a uniform bake. A blade tip which is too thin risks deflection under the pressure of the roller and can lead to serious production issues.

Replacement Blades

As with all blades, rotary scraper blades will wear out eventually. Thankfully, at Precision Edge, we offer a blade replacement service. We can promptly supply replacement blades so that you can reduce production line downtime. We can manufacture bespoke blades with various machining details, angular configurations up to 1500mm in length. We also keep many popular lines in stock. RBS805-1, RBS805-2, RBS805-7, RBS3228, 9342743B, 9343792F, DM30131, 9342896K, 9342742D and many others.

Contact Us

For more information about our rotary knives, or any other products and services, please get in contact via our web contact form, or by email at sales@precisionedge.uk.com. Alternatively, you can speak to a member of the team directly by calling us on 01403 892 510. We will be happy to help you with any queries you may have for us.